Biscuit Business

Early one chilly Friday morning, I arrived at the Phipps Mansion in Denver, Colorado with 75 other supply chain management professionals. Each month, we’d gather to listen to industry leaders speak on how they were innovating in our field. That morning, an executive from the fast food industry shared a story I’ll never forget.

Photo Credit: http://oneperfectbite.blogspot.com

He was working for Kentucky Fried Chicken and was tasked with finding a new supplier for their biscuits. In his search, he discovered a provider in Louisiana that made “the perfect biscuit”. Unfortunately, there was one problem: the Louisiana factory couldn't go lower than 11 cents per biscuit, and KFC's business model couldn't go higher than 10 cents. At 11 cents, the factory would hardly make a profit — at 10 cents, they would lose money.

In pursuit of a solution, KFC sent a team to pinpoint inefficiencies at the factory. Soon after, they fashioned a list of 30 or so ways the factory could improve their biscuit-making process. Given that the factory was a primary employer in a small Louisiana town, the staff was inspired to land this significant KFC contract. And almost immediately, they implemented the first seven or so recommendations. Due to their diligence, they were able to drop the cost of each biscuit to a profitable 10 cents and landed the KFC contract.

Years later, this same executive (who had since accepted a promotion to work at another company) received a call from the general manager at that Louisiana biscuit factory. He said, “Remember that list of improvements you identified? Well, we didn’t stop at the first few. Over time, we implemented each and every recommendation and we’ve brought the cost of each biscuit down to 7 cents. With all our new business, we’ve even doubled our headcount!”

I left that morning feeling so inspired by the impact he and his team had had on that factory. As I walked away from the Phipps Mansion, breathing in that crisp Colorado air, I hoped that one day I’d have the opportunity to do the same.

How Long Does It Take to Paint a Helicopter?

In 2008, as a consultant I worked with one of the world’s largest helicopter operators. Their maintenance division had a host of problems and I was assigned to work with the paint shop. At the time, it was taking them an astounding 27 days to paint a Skiskorsky 76.

Photo Credit: http://barrieaircraft.com

To put this duration in context: other airline clients could paint a (significantly larger) Boeing 747 in only 11 days. I worked with the paint shop team over the next few months, shining light on ways they could improve their painting process.

Our Own List

Using Lean Six Sigma methodologies we identified our own prioritized list of over 20 improvements. These ideas ranged from improved lighting, changing the paint scheme, displaying job status to employees on the shop floor, using higher quality supplies, and building moveable carts to keep materials and tools within arm’s reach.

We calculated that the implementation of all of these procedures could decrease the total paint time to just 13 days. In the following weeks, we saw an immediate, yet modest, reduction in paint time. We also noticed a spike in the engagement and morale of the paint shop staff, as we alleviated some of their frustrations and invested in their workspace. Soon after our contract ended, I wondered if they were willing to follow through with all of the improvement ideas we identified.

Getting My Own Call

Six years later, an employee from the paint shop called me. He said “Hey, remember that list we made of ways to cut the time for helicopters in the paint shop? Well, we’ve been working through it since you left, and we just got our first helicopter done in 13 days! And we’re not done. We want to hit 11 days, maybe even 10 days by the end of the year. BEAST MODE buddy!” I’m so glad he made me laugh, because I was overcome with emotion — feeling pride for their stick-to-itiveness and rigor.

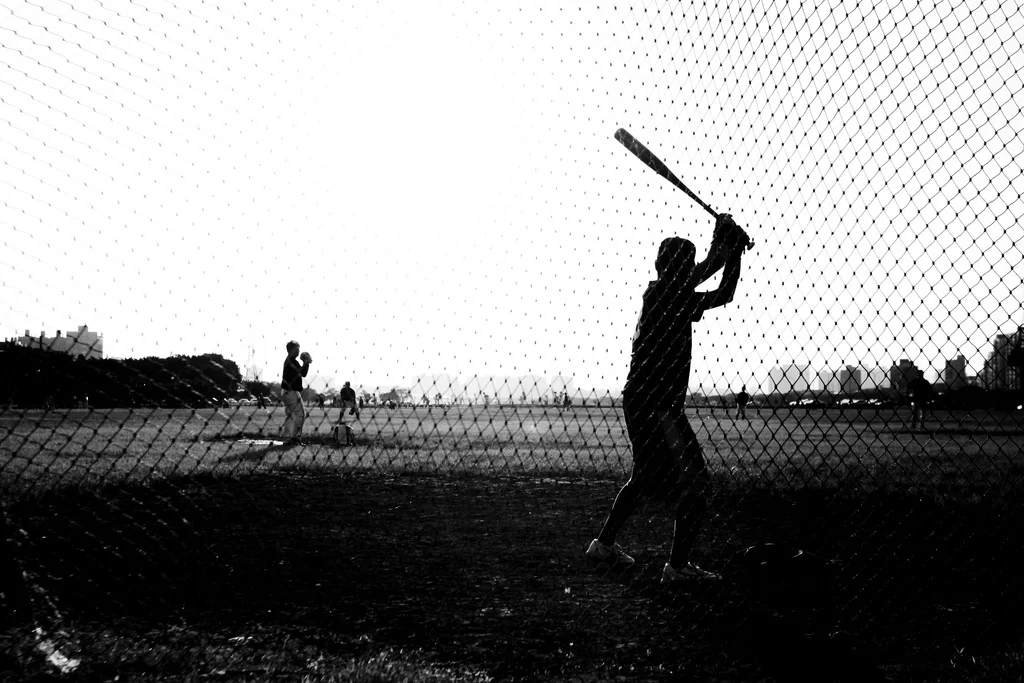

Finish the Swing

Starting things is sexy. We’re easily enticed by new products, new companies, new markets, new hires, new facilities, and new initiatives. Finishing, on the other hand, isn’t nearly as alluring, but it is much more satisfying.

When swinging a baseball bat, the batter never stops their swing once the ball strikes the barrel. Rather, the player must follow through with his swing in order to produce a powerful hit. This concept of finishing the swing is not limited to the world of sports — it is a powerful way to think about leadership and making an impact in your organization. To produce truly decisive and lasting results, you cannot lose momentum once the initial decision is made. Finish the swing.